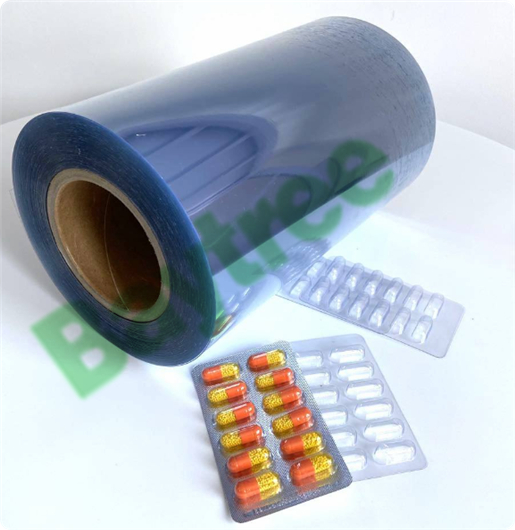

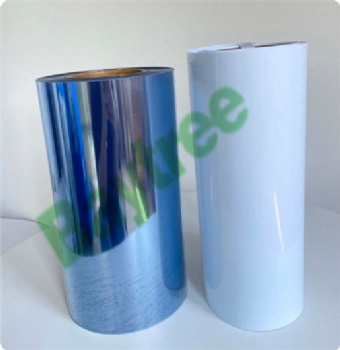

PVC/PVDC/PVC high barrier film

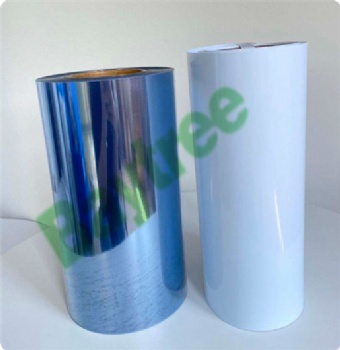

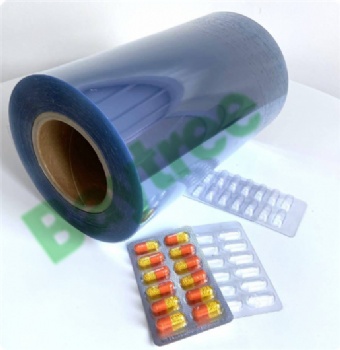

Its core advantages lie in "symmetric stability + high barrier property": the inner and outer PVC layers ensure excellent thermoformability and structural stability, adapting to high-speed aluminum-plastic blister (PTP) packaging machines to fit the shape of tablets and capsules accurately. The symmetric structure also avoids warping caused by uneven stress during forming; the middle PVDC layer provides strong barrier performance, which can significantly reduce the transmission rate of oxygen and water vapor, delaying drug oxidation and moisture-induced failure (e.g., oxidizable antibiotic tablets, moisture-sensitive probiotic capsules).

In addition, the material meets pharmaceutical hygiene standards (no migration of harmful impurities, no pathogenic bacteria) and can be customized into transparent or light-shielding specifications on demand, making it a preferred packaging material for solid preparations that balances forming stability, high protection and compliance.